Drying & Dehumidifying

WSDA Cabinet Dryer For Injection Molding Machine

Widely suitable for drying any plastic r...

1:Hopper with blender prevents lump and deformation.

2:Constant agitation and orientation pole prevent agglomeration

3:Automatically monitors hopper temperature to ensure continuous and reliable output of crystallized material.

4:Processed materials can be currently discharged

Material tank is equipped with a door and detachable blender, and easy to access and clean.

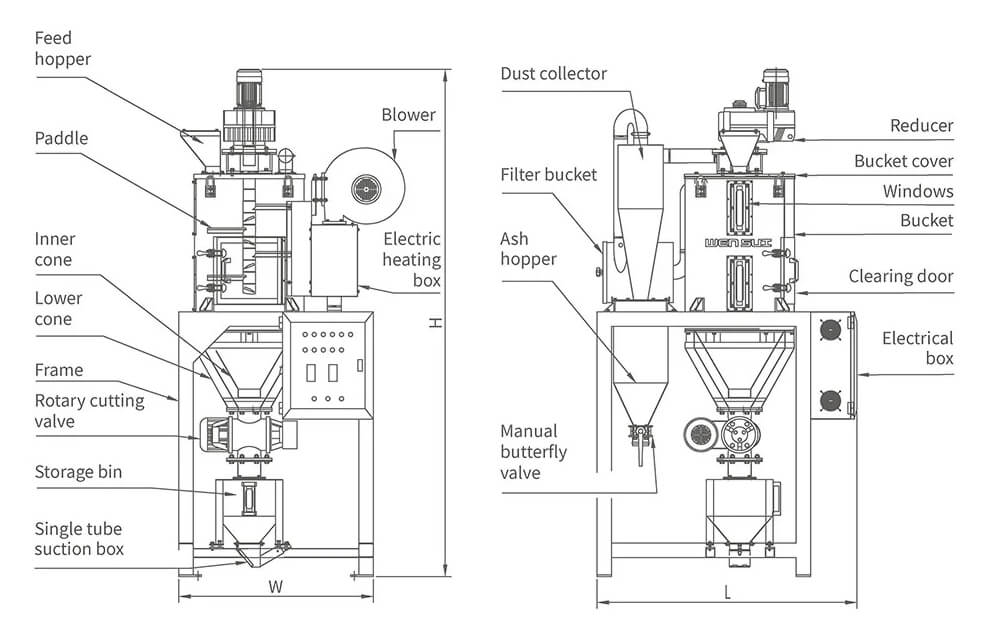

Working Principle

The crystallization system can transform amorphous PET raw material particles into crystalline form for drying, and dry at high temperatures to obtain low moisture raw materials without worrying about agglomeration. It consists of a high-temperature heat source, an insulated hopper with a stirrer, and a rotating discharge valve, and can be easily paired with other raw material processing equipment.

Performance characteristics

Reliable and high-quality raw material output; Complete structural and control design to prevent raw materials from clumping and deformation.

Mixing hopper to prevent agglomeration; The uniquely designed mixing blades and positioning rods ensure that the raw materials are frequently rolled to crush any possible clumps and prevent clumping during processing.

Automatic continuous operation; Automatically detect the internal temperature of the hopper to ensure the output of high-quality crystalline raw materials.

Meeting the needs of different raw materials; It can be directly processed online or processed in batches and stored as crystalline raw materials for future use.

Designed to be safe and easy to clean; The flexible design of the entrance door and movable cone bottom allows the mixer to be moved away from the top or bottom, making it convenient for material cleaning.

Power supply: 3 Φ 380VAC 50Hz;

The product specifications are subject to change without prior notice.